The positive for the fuselage.

The 2 last days have been spent working on the positive for the fuselage mould. The positive is made from three pieces of 10mm. balsa glued together. The center piece is hollowed out and a 10mm. carbon rod is glued in with glass rowing and cotton flock as filler. The three pieces are then weighted down on a flat surface that is checked for squareness. when the balsa block is dry, a lot of carving and sanding is done and the shape is checked with a lot of templates. Then the positive get a coating of fiberglass and epoxy. For the basic shaping of of the positive excluding tail and wing mounts, it took me a whole 7 hours. Then another hour to coat with epoxy.

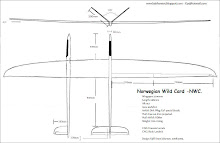

Here you can see the finished result. The super fat tail mount area is not prepared at all and will look a lot better when it get some TLC. The triangular shape of the tailboom is clearly visible. The triangular shape has the wide part on top. This is reverse of the Freestyler 3 . The main reason is looks and the way the tail is going to be mounted with "pull for up".

Here you can see the finished result. The super fat tail mount area is not prepared at all and will look a lot better when it get some TLC. The triangular shape of the tailboom is clearly visible. The triangular shape has the wide part on top. This is reverse of the Freestyler 3 . The main reason is looks and the way the tail is going to be mounted with "pull for up".

So far happy with the result.

So far happy with the result.

Comparing to my Furio 3 (2 piece v-tail) the front of the fuse is about 3mm lower in height. Its also 10mm ore narrow and a tadd more squaresided. The max thickness is 30mm. Can`t get much thinner than this if there is going to be room for servos inside.

Comparing to my Furio 3 (2 piece v-tail) the front of the fuse is about 3mm lower in height. Its also 10mm ore narrow and a tadd more squaresided. The max thickness is 30mm. Can`t get much thinner than this if there is going to be room for servos inside.

The 10mm. carbon rod inside the positive.

The 10mm. carbon rod inside the positive.

Here you can see the finished result. The super fat tail mount area is not prepared at all and will look a lot better when it get some TLC. The triangular shape of the tailboom is clearly visible. The triangular shape has the wide part on top. This is reverse of the Freestyler 3 . The main reason is looks and the way the tail is going to be mounted with "pull for up".

Here you can see the finished result. The super fat tail mount area is not prepared at all and will look a lot better when it get some TLC. The triangular shape of the tailboom is clearly visible. The triangular shape has the wide part on top. This is reverse of the Freestyler 3 . The main reason is looks and the way the tail is going to be mounted with "pull for up". So far happy with the result.

So far happy with the result. Comparing to my Furio 3 (2 piece v-tail) the front of the fuse is about 3mm lower in height. Its also 10mm ore narrow and a tadd more squaresided. The max thickness is 30mm. Can`t get much thinner than this if there is going to be room for servos inside.

Comparing to my Furio 3 (2 piece v-tail) the front of the fuse is about 3mm lower in height. Its also 10mm ore narrow and a tadd more squaresided. The max thickness is 30mm. Can`t get much thinner than this if there is going to be room for servos inside. The 10mm. carbon rod inside the positive.

The 10mm. carbon rod inside the positive.

0 Comments:

Post a Comment

<< Home