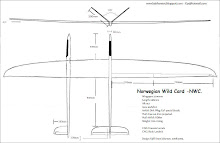

How the finished NWC is going to look like...

Above is the 3-plan view of the NWC, and it is the result of my lack of drawing skills.... But it will give you an idea of what the finished plane is going to look like.

Right now I`m spending alot of time making work flow charts and packing lists to have everything ready to travel to my parents in Lofoten as soon as I receive the positives from Bodo. The plan is to spend a month there to make the wing moulds. The days are going really slow and waiting for the postives is not fun at all, but they are in Oslo now, and moving slooowly up north...

I would also use the oportunity to say thanks to Francois Lorrain, Bodo Landeck and Dirk Pflug for helping out! These guys has spendt alot of hours to help me get the plane design just the way I want it. They have also done all they can to keep my costs as low as possible. Without them, this project would`nt have happened. Thanks alot guys!

Project documentation starts at december 2008.....